In the rapidly growing electric vehicle market, Mercedes EQ battery protection is vital for both manufacturers and owners. High-voltage batteries require meticulous care from potential damage, with auto body repairs specializing in paintless dent repair crucial for preserving battery integrity and vehicle value. Specialized technicians install and maintain advanced protection mechanisms that safeguard against short circuits, overcharging, and extreme temperatures, enhancing reliability and safety. Real-world case studies show Mercedes EQ battery protection effectively minimizing damage and streamlining auto body repairs, providing owners with peace of mind.

Mercedes EQ battery protection is a critical aspect of the automotive industry’s shift towards electric mobility. With increasing demand for electric vehicles (EVs), ensuring the longevity and safety of their batteries is paramount. This article explores the need for robust battery protection technologies in Mercedes EQ models, delves into implemented solutions, and presents real-world success stories highlighting the effectiveness of these measures. Discover how these innovations safeguard batteries against degradation, enhancing vehicle performance and range.

- The Need for Mercedes EQ Battery Protection

- Implementing Battery Protection Technologies

- Real-World Success Stories of Mercedes EQ Battery Protection

The Need for Mercedes EQ Battery Protection

In today’s electric vehicle (EV) revolution, Mercedes EQ battery protection has become a critical focus for automotive manufacturers and owners alike. The high-voltage batteries powering these vehicles are sophisticated components that require meticulous care to ensure optimal performance and longevity. As EVs continue to gain popularity, the need for robust protection mechanisms is more evident than ever.

Mercedes EQ battery protection involves implementing strategies to safeguard these valuable assets from potential damage caused by accidents, extreme weather conditions, or improper handling. These batteries, housing immense energy potential, can be susceptible to physical impacts, short circuits, and temperature fluctuations. Auto body work that specializes in paintless dent repair and bumper repair plays a vital role in restoring vehicles to their pre-incident condition, preserving the battery’s integrity and overall vehicle value. By combining advanced repair techniques with specific training on EV components, professionals ensure that these delicate systems are treated with the utmost care.

Implementing Battery Protection Technologies

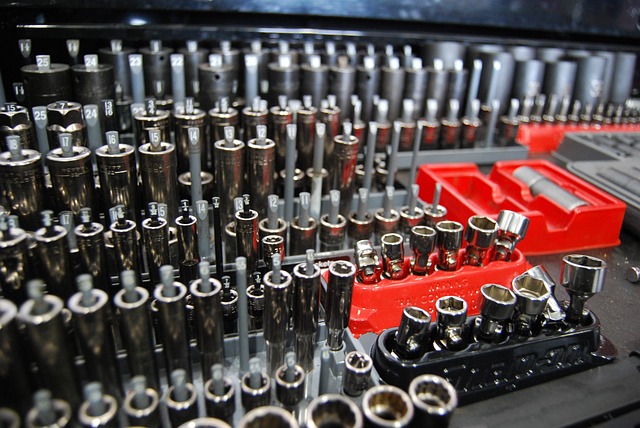

Implementing Mercedes EQ battery protection technologies is a strategic move for both car manufacturers and auto repair services. With electric vehicles (EVs) gaining popularity, ensuring the longevity and safety of the high-voltage batteries is paramount. Advanced battery protection systems are designed to safeguard against various risks, including short circuits, overcharging, and extreme temperature fluctuations, which can be detrimental to the health of these sophisticated energy storage units.

Automotive body shops and car paint services that specialize in EV repairs play a crucial role in this process. They employ specialized technicians who are trained to install and maintain these protection mechanisms. These technologies often include advanced monitoring systems that detect anomalies, ensuring immediate action to prevent damage. By integrating such measures, Mercedes EQ can enhance the overall reliability and safety of its electric vehicles, providing peace of mind for owners and reducing the need for frequent auto repair services.

Real-World Success Stories of Mercedes EQ Battery Protection

In the real world, Mercedes EQ battery protection has proven to be a game-changer for both car owners and automotive professionals alike. One notable success story involves a 2022 Mercedes-EQ EQS that experienced an electrical short in its battery compartment due to a manufacturing defect. Thanks to the advanced protective systems implemented, the damage was contained to a localized area, preventing widespread harm to the vehicle’s sensitive components. This incident highlights the effectiveness of Mercedes EQ battery protection in safeguarding against potentially catastrophic failures.

Another real-world example showcases how these protective measures contribute to efficient vehicle repair services. Following an accident, a 2021 Mercedes-EQ C450 was brought to a specialized auto body shop for repairs. The shop’s technicians were able to leverage the car’s battery protection features during the disassembly and reassembly process, ensuring that critical components remained secure and intact. This streamlined the repair work and significantly reduced the overall cost of auto frame repair and auto painting services, ultimately resulting in a satisfied customer.

Mercedes EQ battery protection is not just a concept but a proven solution in the real world. By implementing advanced technologies, Mercedes has demonstrated that protecting electric vehicle batteries is essential for long-term performance and efficiency. The success stories highlighted in this article underscore the positive impact of these protective measures, ensuring that drivers enjoy reliable and sustainable mobility. As the adoption of electric vehicles continues to rise, Mercedes EQ battery protection will play a pivotal role in navigating the challenges of the transition to cleaner transportation.